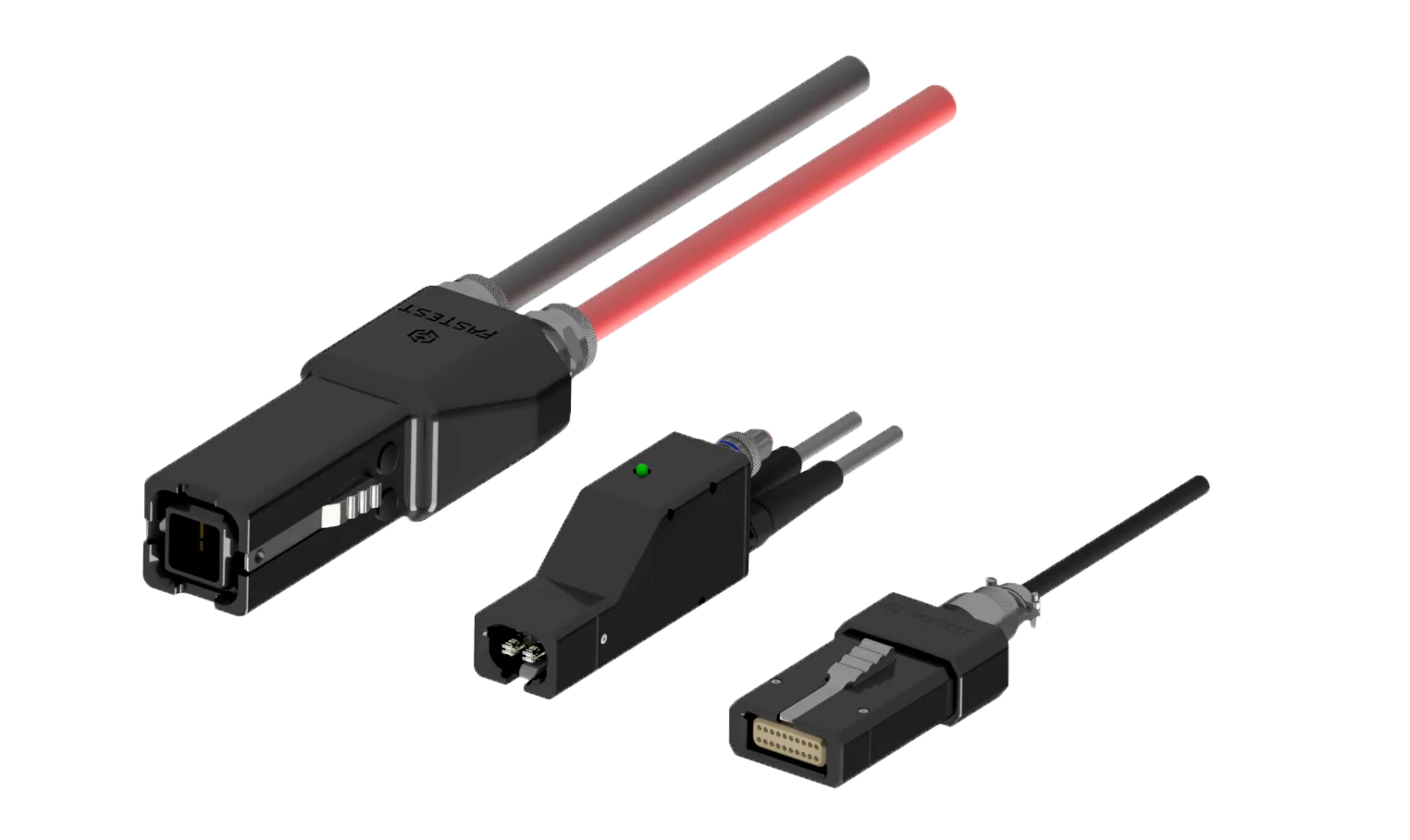

High-Voltage and Low-Voltage Electrical Test Connectors

New HeaderMate EHE Electrical Test Connectors for High Volume EV Battery and Powertrain Production

New HeaderMate EHE Electrical Test Connectors for High Volume EV Battery and Powertrain Production

EHE Electrical Test Connectors from FasTest are designed to survive the rigors of high-volume

vehicle production testing. Leveraging FasTest’s 40+ years of experience designing superior quick connect solutions that last, the EHE was engineered to provide up to 50,000 cycles of trouble-free operation between maintenance intervals. Field-replaceable pins and contacts minimize downtime

to ensure maximum productivity. As with all FasTest products, local service and support are available through our global network of factory authorized distributors.

Precision engineered tools provide the highest quality connection and seal for accurate testing.

Easy-to-use one hand operation, eliminate the painful twisting motions of standard fittings.

FasTest’s ergonomic tools instantly attach to ports and threads - no wrenches, thread tape, or sealants for a leak-tight seal.

Multiple safety features are included in every tool, including pressure assisted sealing technology.

Engineered for precision and durability to withstand rigorous testing environments.

Engineered for the highest quality connection and seal. Reduce False Failures caused at the connection points.

Complete Battery Package and EV testing solutions.

Connection tools for leak testing motors, inverters and coolant lines for both the electric vehicle and internal combustion engine markets.

Connection tools designed for your engine. Maximize efficiency and safely connecting to transfer fluids, leak testing, or plugging any port.