Automotive Customs

Improve operator safety, connection time, testing accuracy and quality.

Improve operator safety, connection time, testing accuracy and quality.

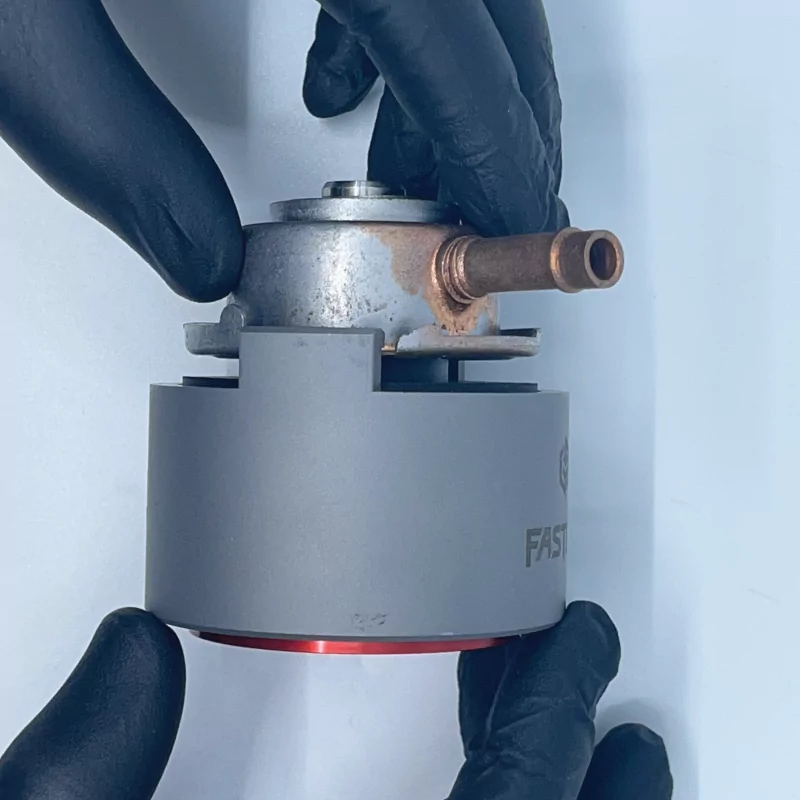

FasTest was tasked by a major Automotive Engine manufacturer to produce a secure sealing connection to their radiator fill necks. Before FasTest, there was no solution for this application.

The customer was manually sealing the radiator fill neck with fill caps that required manual twisting - this resulted in inconsistent seals and strain on the operator. The fill port was also hard to access which resulted in dangerous methods to reach it

FasTest needed to create a way to seal on the fill neck, issues with this: little sealing surface, a wide diameter, and an internal seal.

FasTest was able to create custom Connection Tools which offered accurate seals and increased safety - Improving the customer’s sealing connection.

Less injuries and lost time

Increased throughput

Instant leak-free connections

FasTest was tasked by a major generator manufacturer to produce secure sealing connections for their 45-liter, 60-liter, and 78-liter diesel engines. The customer was looking to upgrade their process by improving speed and accuracy on their end-of-line quality test.

The customer was manually wrenching and bolting on mating fittings to all the connection ports by hand - this resulted in strain on the operators and longer test times.

FasTest needed to create a wide range of solutions that needed to meet the customer's pressure and test requirements. Some challenges with this project included the overall size of the Connection Tools as well as working around interference issues within the customer's Genset.

FasTest designed and manufactured new and unique designs that were tailored to the customer's test cell. By doing this we improved reliability, safety, and efficiency.

Less injuries and lost time

Increased throughput

Instant leak-free connections

Submit a custom application form and drawing to fastsales@fastestinc.com or to your local distributor.