Leak Test Solutions for Motors and Inverters

A high-quality, repeatable leak test is crucial for high-volume EV motor and inverter production. Even a small leak under the electrical headers or cooling ports could cause a failed leak test and allow a defective product to be identified.

The electrical header connections mounted on motors, inverters, and EV batteries are generally brightly colored, glass-filled polymers. Electrical header port sealing requirements have presented a significant challenge for EV engineers trying to achieve a leak-tight seal with consistent compression around the port perimeter, particularly where small radius corners are present. While traditional o-ring seals are designed to effectively seal circular openings, EV battery pack electric header connections are often square, rectangular, or oval.

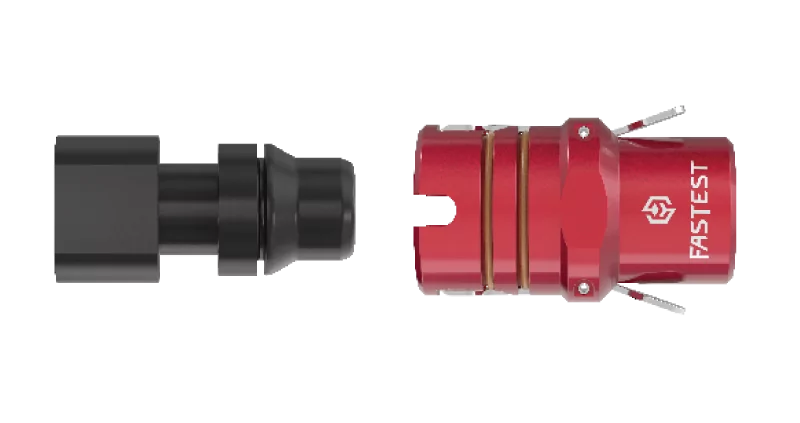

To overcome this challenge, FasTest partnered with EV industry leaders to create a superior sealing, longer-lasting solution. Our new BEV family of leak test connectors incorporates a proprietary actuation and seal design that provides a consistent seal around the entire perimeter of non-circular ports, in addition to the durability, accuracy, and consistency demanded by engineers working on high-volume EV production.

Connection Tools for Motors & Inverters

Manual Connections to BEV Electrical Headers

Manual Connections to VDA Ports

Manual Connections to Threaded Ports

Manual Connections to Fuel Rail Ports with ICON™

Automated Connections to BEV Electrical Headers

Automated Connections to VDA Ports

Why FasTest for Motor & Inverter Leak Testing

Accurate Connection & Sealing

Precision engineered tools provide the highest quality connection and seal for accurate testing.

Reduce Repetitive Motion Injuries

Easy-to-use one hand operation, eliminate the painful twisting motions of standard fittings.

Safely Connect in Seconds

FasTest’s ergonomic tools instantly attach to ports and threads - no wrenches, thread tape, or sealants for a leak-tight seal.

Safety First

Multiple safety features are included in every tool, including pressure assisted sealing technology.

Durable Connection Tools

Engineered for precision and durability to withstand rigorous testing environments.

Quality Tools, Quality Tests

Engineered for the highest quality connection and seal. Reduce False Failures caused at the connection points.

Trusted by Industry Leaders

Custom Engineered Solutions

We transform connection tools into tailor-made solutions to fit your exact requirements. Our Team of engineers will work with you to identify and design the optimal Connection Tool for your testing needs. Having difficulty sealing a unique port? Issues with clearance? Work with our dedicated team of Custom Experts to build your perfect solution.

Automate Your Leak Test Process with

ICON™ Intelligent Tools.

ICON™ is a process automation enabling technology engineered to enhance and maximize our customer’s testing process.

- Verify safe connections and reliable sealing.

- Confirm step completion and set handshake points.

Integrating sensing and real-time data output into FasTest’s industry-leading connection tools. ICON™ puts the power in the hands of users to run smarter, safer, and faster tests. Whether you're making a manual connection or integrating automation, ICON™ technology has a connection solution for you.

Related Vehicle System Applications

Connection tools designed for your engine. Maximize efficiency and safely connecting to transfer fluids, leak testing, or plugging any port.

Tailored connection tools for a full battery pack leak test. Develop the ideal connectors to meet your needs/requirements.

Connection tools for all your automotive leak testing and fluid transfer needs.

Contact a Motors & Inverters Expert