Customer

A leading global supplier of medical, industrial and specialty compressed gas.

Application

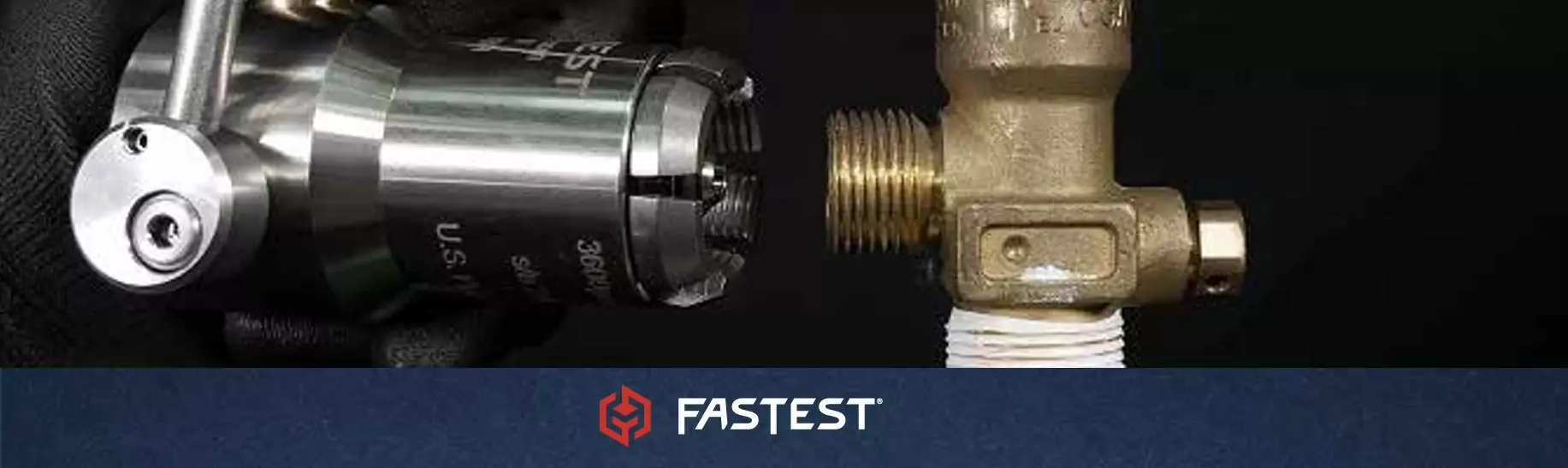

A high-volume fill plant is currently filling cylinders with twist-on connectors on CGA 346 (compressed air) manifolds.

Challenge

Decrease cycle time to fill more air cylinders on existing CGA 346 racks. Due to the use of manual twist-on connectors, cycle times were unnecessarily long creating a bottleneck in production. Also, the cylinders were palletized (closely bundled) during filling presenting a significant space constraint for any connector solution.

Project Goals

• Minimize cycle time and eliminate the ergonomic safety hazard of the twist-on connections to fill more cylinders.

• Increase overall process safety

Solution

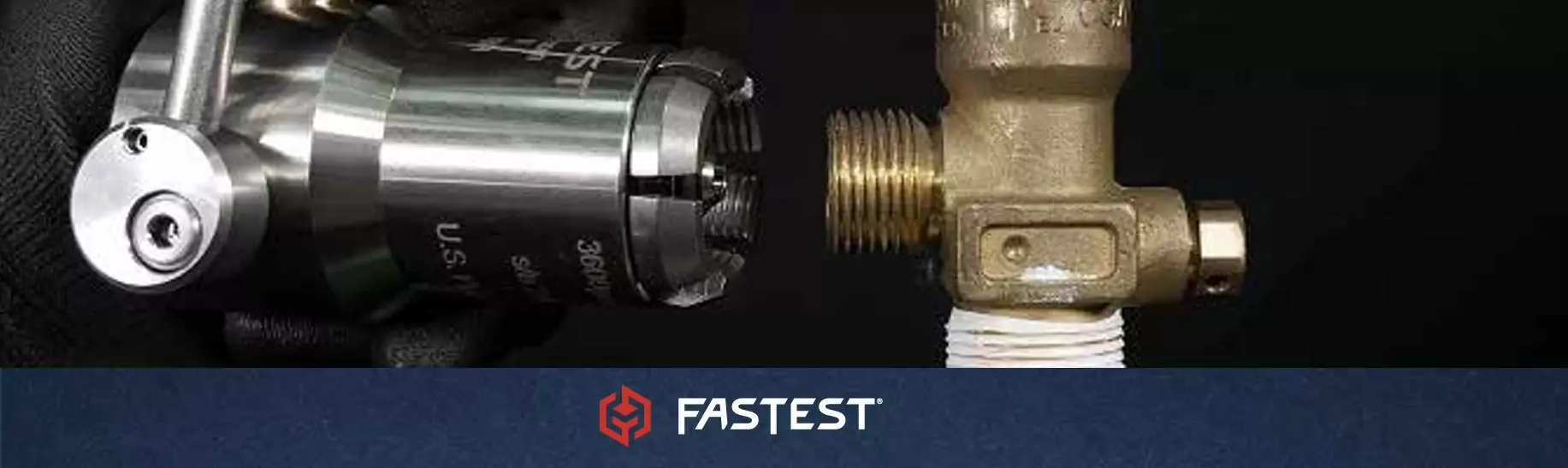

FasTest’s G346 connector with the small number 1 rigid handle was chosen to fit within the palletized (closely bundled) cylinders.

Results

The new G346 connectors from FasTest significantly reduced fill cycle time and eliminated the ergonomic safety hazard. Production efficiency increased, and the time saved connecting now allows time for filling one additional rack per day. The process for filling CGA 346 cylinders no longer takes more time than the CGA 580 and 540 cylinders elsewhere in the plant that already utilized FasTest quick connectors. Additionally, the operators are quite happy with the new FasTest G346 connectors’ speed and ease of use, and of course the reduced wear and tear on their wrists!