ICON™

ICON™ is a process automation enabling technology engineered to enhance and maximize our customer’s testing process.

ICON™ is a process automation enabling technology engineered to enhance and maximize our customer’s testing process.

Integrating sensing and real-time data output into FasTest’s industry-leading connection tools, ICON™ puts the power in the hands of users – or robots – to run smarter, safer, and faster tests. Improve testing quality and lower manufacturing costs with ICON™.

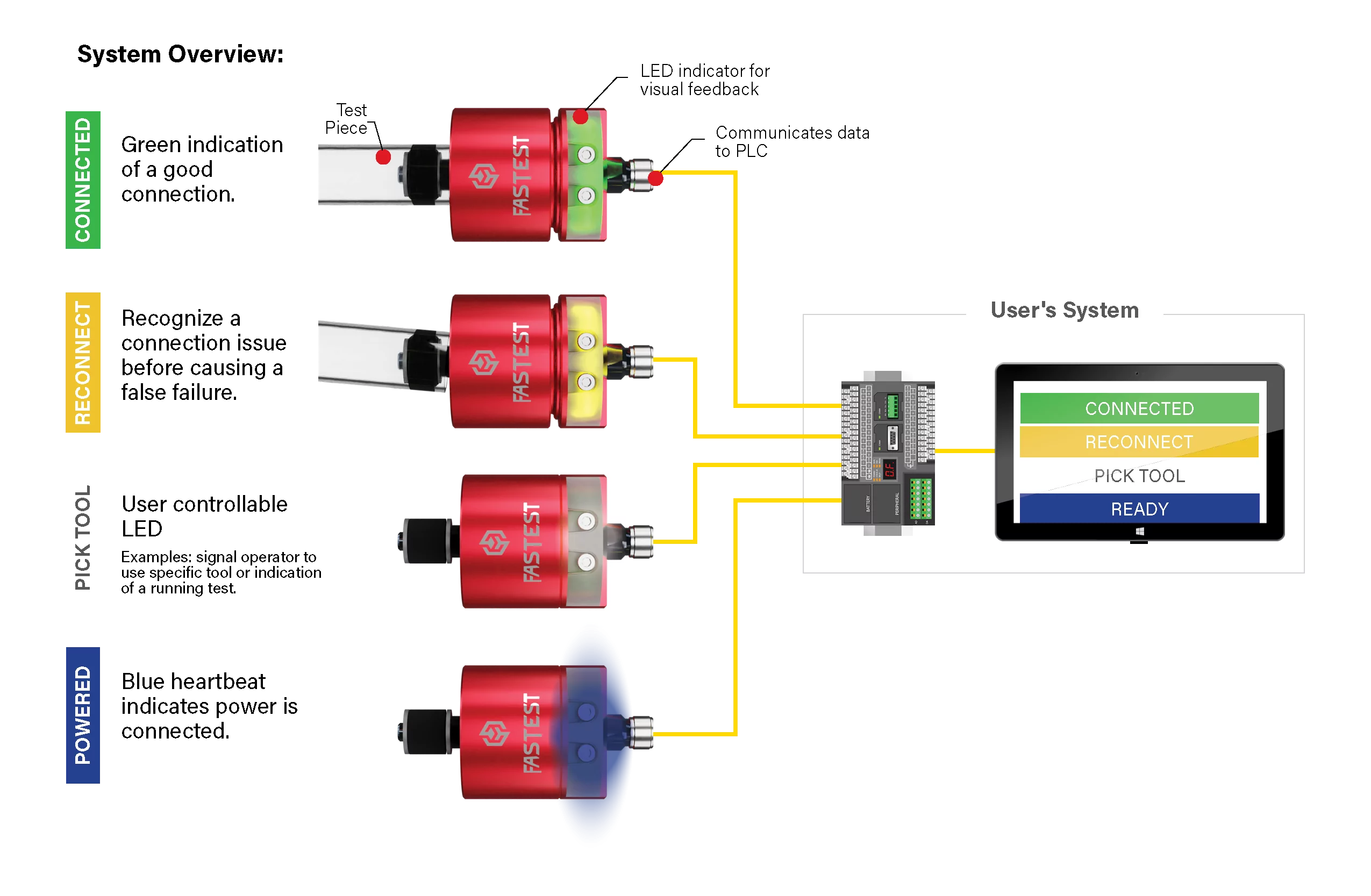

Yellow indication of a miss-connect or short-connect. Reconnect for green indication.

User controllable white indication allows user’s to tailor to their testing process. Examples include setting a signal to operators to use a specific tool, or an indication that a test is running and to not remove connector.

Blue heartbeat indication that power is connected.