PortMax™

High Flow Access Port System for Rapid Evacuation of HVAC-R Packages

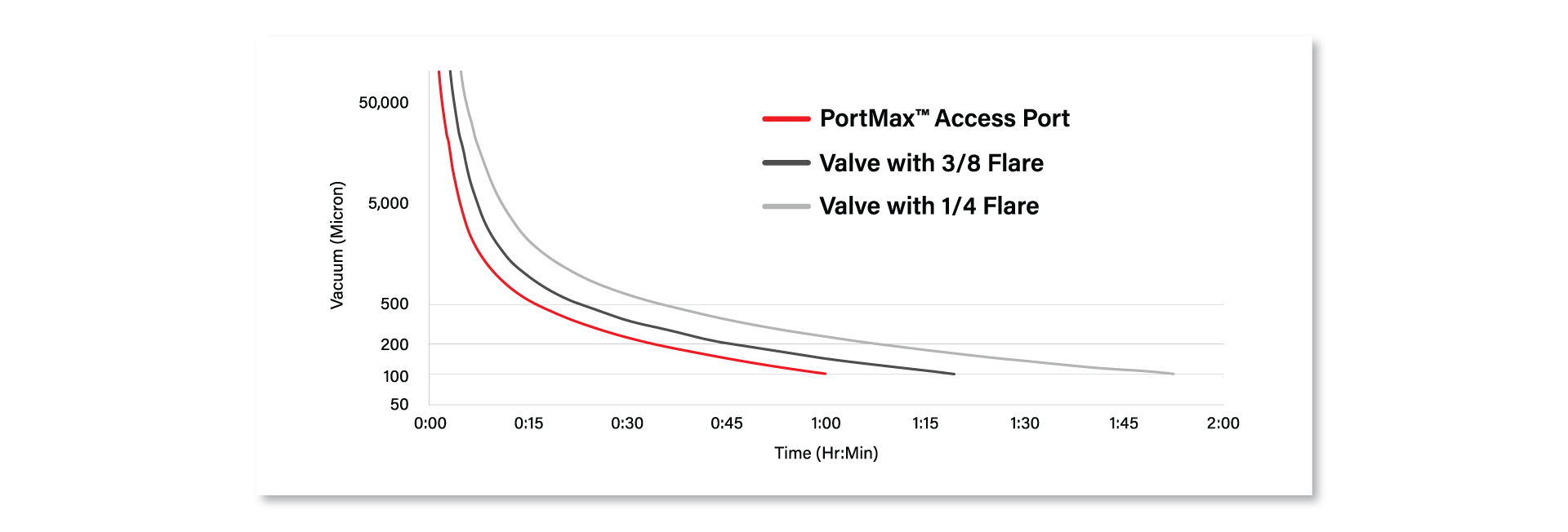

Speed up the lengthy evacuation process of large chiller, industrial & commercial packaged refrigeration systems --- 45% or more reduction in evacuation times compared to commonly used Packed Angle and Ball Valves.

The degassing/dehydration evacuation process is a common bottleneck when manufacturing large refrigeration systems, often taking many hours to complete. The use of small, flow-restrictive packed angle and ball valves is a major contributing factor that slows production Takt time during leak test filling, evacuation, and refrigerant charging processes.

Decrease evacuation time (degas/dehydrate) of large volume refrigerant systems currently processing through packed angle or ball valves.

Manufacturing, Chemical, Petro-Chemical, Power Plants

Grocery/Supermarkets, Strip Malls, Office Buildings, Ice Rinks, Server Farms

Chillers used in air conditioning and many industrial/laboratory applications

Food Warehouses, Grocery Super Stores, Pharmaceutical Facilities

Office & Apartment Buildings, Hotel, College Campus, Multi-Use Facilities. Rapidly evacuate extremely long tubing runs typical in these applications.

Industrial Facilities, Warehouses, Industrial Kitchens/Food Service Facilities

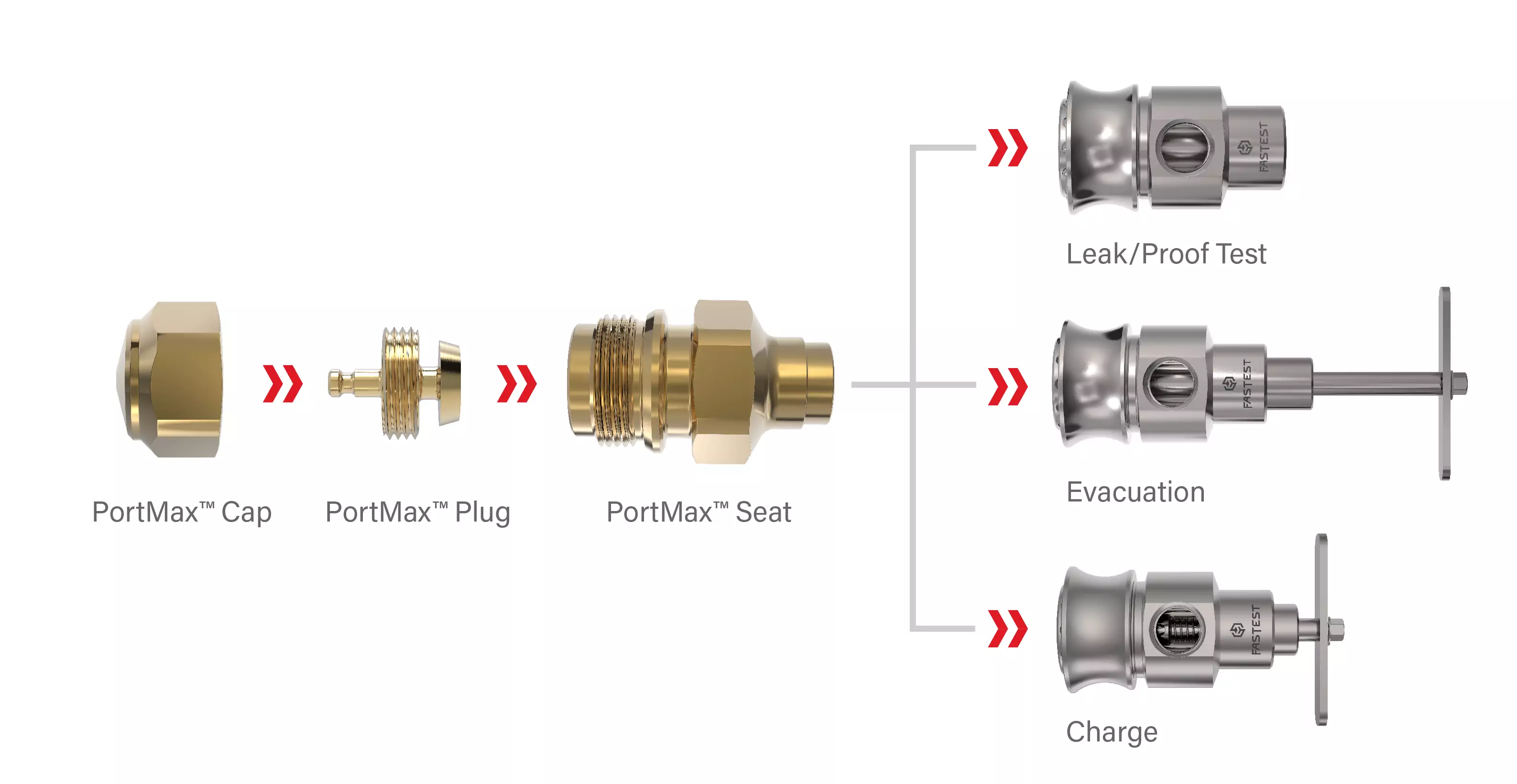

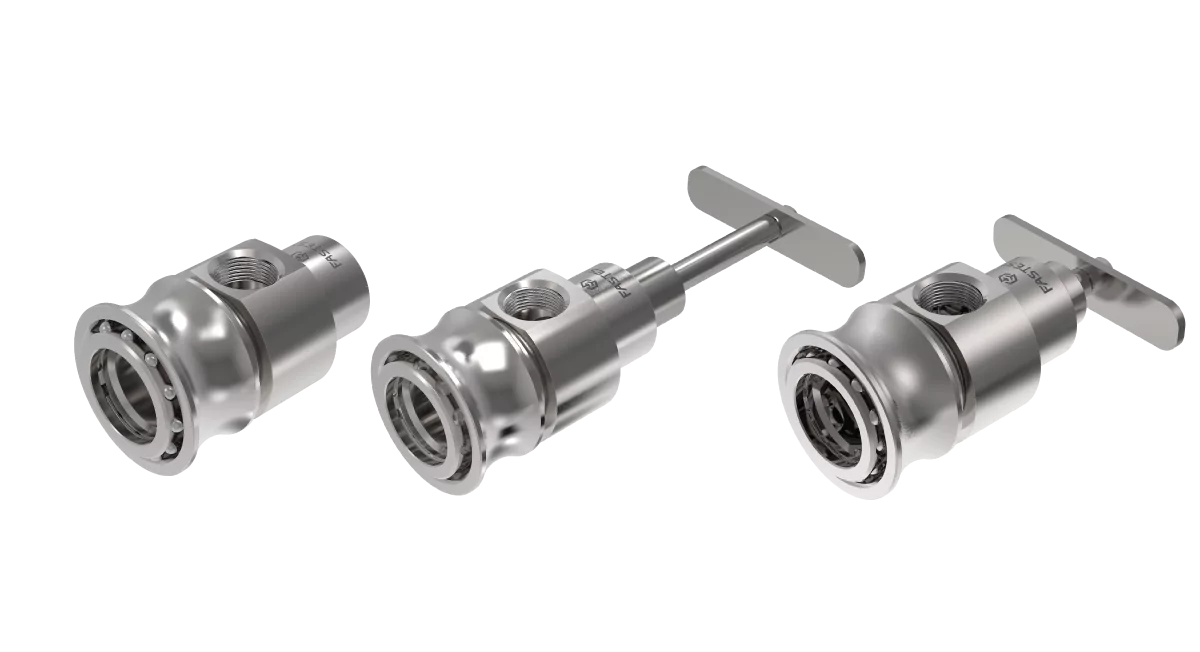

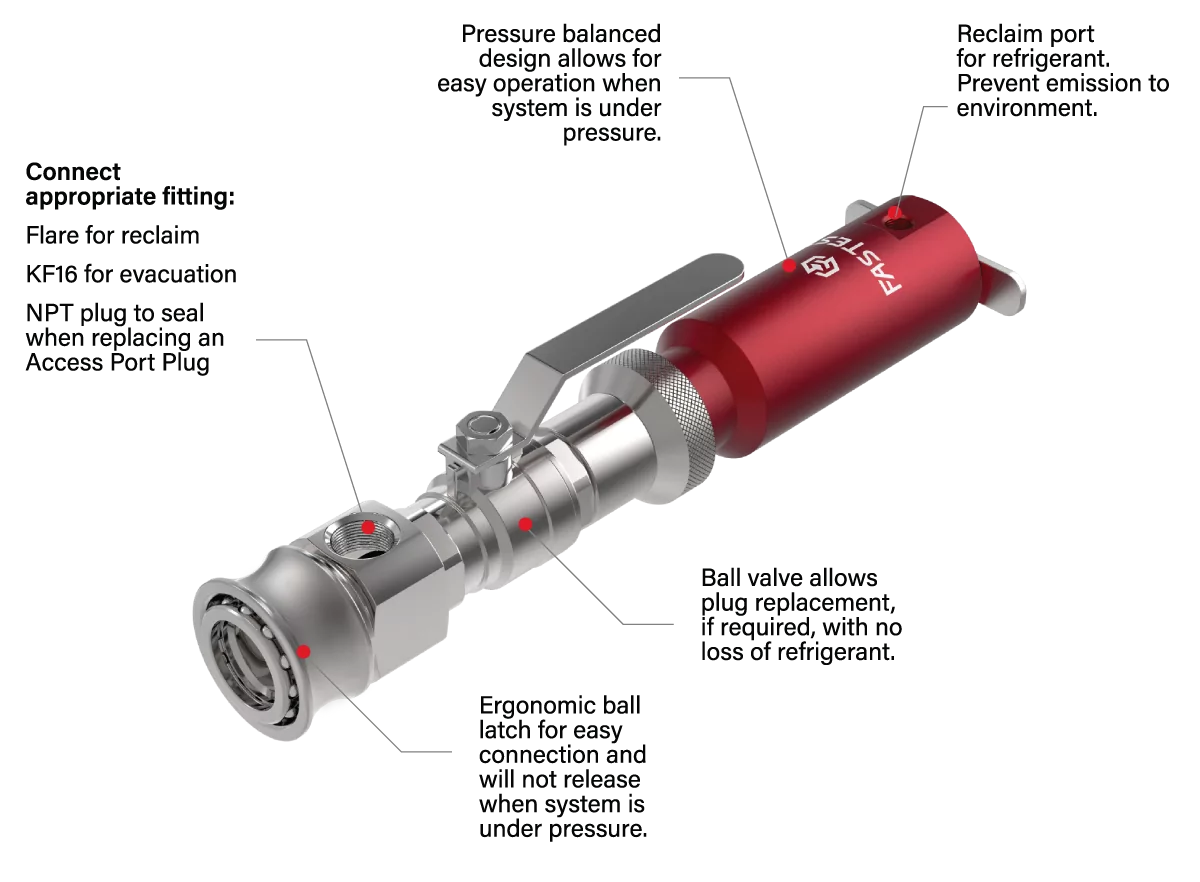

Gain access to the refrigerant system for servicing. Designed to provide installation & service technicians with a single tool that can be used to perform multiple tasks - refrigerant reclaim, leak test, evacuation, charge and replace a PortMax™ access port plug without losing refrigerant charge.

Fully automated evacuation cart for optimized refrigeration system processing with real-time monitoring and data acquisition.

Fill out this form to get in contact with a FasTest Connection Expert.