FasTest Access Ports

Complete solutions for efficient processing and leak testing of HVAC refrigerant systems.

Complete solutions for efficient processing and leak testing of HVAC refrigerant systems.

Quick connections, the highest available flow rates, zero-emissions, safe operation and 100% compatibility with 21st century, environmentally friendly refrigerants.

Want to learn more? Reach out to an Access Port Specialist for assistance on the right access port for you application.

![]()

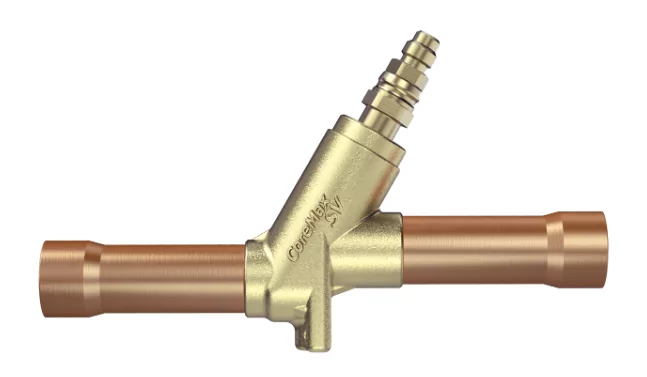

The CoreMax® access valve system provides up to five times greater processing flow than common Schrader® valves and the integral shut off valve has dramatically improved sealing performance. The 1/4 flare profile is compatible with standard processing and service tools.

Anywhere a Restrictive & Leak Prone Schrader Valve is Used.

![]()

The NEW PortMax™ access port system is specifically designed to reduce processing time, in particular, evacuation time (degass/dehydrate) of large volume refrigerant systems currently processing through packed angle or ball valves.

The Evacuation Cart is a turn-key, optimized solution with real-time tracking and data capabilities directly from FasTest.