CoreMax™ System

A complete solution for efficient process and leak testing of HVAC refrigerant systems.

A complete solution for efficient process and leak testing of HVAC refrigerant systems.

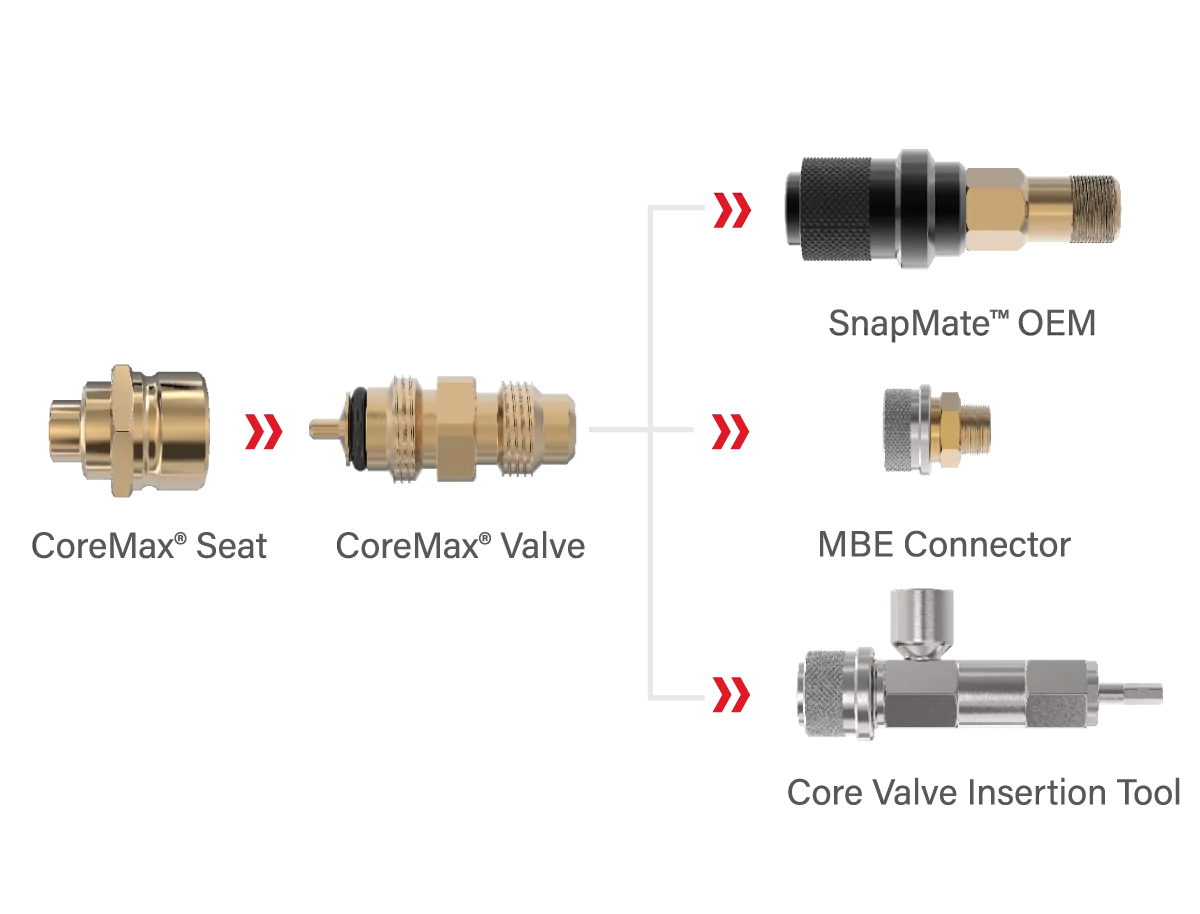

The CoreMax Access Valve & Seat System provides up to five times greater processing flow than common Schrader® valves and has dramatically improved sealing performance. Plus, it provides easy and reliable system accessibility compared to stub tubes and leak prone ”Schrader Valves”.

CoreMax Tools are designed to work seamlessly with the CoreMax Access Valve in all processing stages (Leak/Proof Test, Evacuation, Charging, Run Test, Final Fill & Reclaim/Rework). Together they form a flexible system that shortens processing times, while improving the quality of refrigeration products. The new CoreMax RQD Tool also now makes it possible to charge refrigerant without venting any refrigerant to the atmosphere, e.g. “Zero Emission Processing”.

Unlike other systems, this is an integrated system design that has been specifically designed to OPTIMIZE OEM PROCESSING IN AN ENVIRONMENTALLY SUSTAINABLE MANNER, ELIMINATE ACCESS PORT LEAKS, and MAKE FIELD SERVICING EASY!

The CoreMax® System eliminates process tubes and Schrader® valves for dramatically faster evacuation times, improved quality, i.e less leaks, improved TAKT Time, and lower maintenance costs.

Faster Processing

Integral Shut Off Valve

Superior Sealing

CoreMax is more than an Access Valve alone. The suite of Processing Tools allows for an easy, safe and reliable connection in all processing steps. Connectors are “failsafe” and eliminate the possibility of accidental disconnect and dangerous refrigerant discharge!

FasTest Service Tools, the “CoreMax Valve Removal Tool” and the “SnapMate™ Service Tool” allow installation and service technicians to gain access to the refrigerant system in the field. The Valve Removal Tool can be used to replace a CoreMax® access valve without requiring that the system refrigerant charge be reclaimed first. The SnapMate Service Tool allows addition or reclaim of refrigerant from the system. Technicians can perform multiple tasks - refrigerant reclaim, leak test, evacuation, charge and replacement of the CoreMax® access valve without losing refrigerant charge.

Fully automated evacuation cart for optimized refrigeration system processing with real-time monitoring and data acquisition.

With the advantages of FasTest’s leak-tight CoreMax high-flow valve, the CoreMax service valve and single processing tool provide high flow zero emission processing to improve manufacturing efficiency and reduce tooling costs.

The ZeroMax™ access port system is specifically designed to eliminate the need for Process “Stub” Tubes, while adding easy access without sacrificing hermetic metal-to-metal sealing.

Speed up the lengthy evacuation process of large chiller, industrial & commercial packaged refrigeration systems --- 45% or more reduction in evacuation times compared to commonly used Packed Angle and Ball Valves.

Optimized Mobile Evacuation Cart. EvacMax provides rapid and automated evacuation with real-time process monitoring and data acquisition. Technicians now have the ability to set testing targets, start the evacuation and walk away.

Fill out this form to get in contact with a FasTest Connection Expert.